Technical & Quality Audits give importers an idea of the reliability and the capacity of a factory.

Technical & Quality Audits give importers an idea of the reliability and the capacity of a factory.

When?

- Before issuing an order or wiring a deposit: assessment of a potential manufacturer.

- Measurement of the improvement of an existing supplier over time.

What for?

QCP’s audits provide you precise ideas concerning:

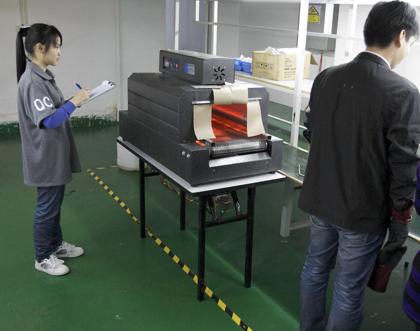

- General organization and process flows of the facility.

- Products currently on the lines: monitor daily activity.

- Machines & employees: equipment type, efficiency of workers.

- Professionalism: existing licenses & certificates verified.

- Production capacity estimation for your products.

- In-depth analysis of facilities’ quality management system.

For small factories (below 400-500 workers), checking the quality system in depth is not realistic. For such cases, we offer a Basic Factory Audit.

Objective: pinpointing the manufacturer’s weaknesses.

- Your decisions are based on due-diligence (“Are they reliable and what production can we give them?”).

- The manufacturer is educated on their weaknesses and areas of improvement.

By whom?

A trained auditor, familiar with ISO9001 requirements.

How much?

From 650 USD per day of work in main areas of operations

The QCP approach

Small manufacturers generally have no quality system in place, so only relying on an audit would not lead to an accurate conclusion.

We encourage our clients NOT to base their decisions ONLY on the audit score of potential suppliers:

- Smaller manufacturers are better for smaller orders, yet they tend to get lower scores in this type of audits.

- A good complement to audits is background/credit checks (for example, is the company profitable? does your supplier really own the factory?)